Just outside of Buenos Aires, upon a patchwork of cornfields and cow pastures where gauchos still roam, a grassroots movement is taking shape. One farmer looking to cut costs and offset rising fuel prices has turned to biodiesel and is proving he can make it himself.

“There are times on the farm when you’re in mid-harvest and there’s not enough fuel,” explains Georges Breitschmitt, a soybean and corn farmer on the Pampas, the expansive plains that surround Argentina’s capital. But while others are lined up at the gas station waiting on deliveries of diesel, the tractors on the Breitschmitt family farm are chugging along on homemade biodiesel, leaving the smell of french fries behind them.

Argentina recently nationalized its oil industry in hopes it would increase production without Spanish oil company Repsol. But the move has somewhat backfired: the country has gone from being a net oil exporter to an importer. Oil production has fallen, exploration is stagnant, and the now state-owned oil company YPF has just announced a 3% price hike at the pumps on all fuels.

“I was using 600 dollars in fuel for every ton of soybean I harvested,” Breitschmitt says. “It was adding up.” Breitschmitt got the idea to produce biodiesel after living in Barcelona. He was impressed by how “up-to-date Spaniards were with renewable energy.” Breitschmitt started looking for industrial-size machinery to produce his biofuel, but a machine that cost $25,000 in the United States would set him back $60,000 in his own country thanks to Argentine import taxes. It just wasn’t an option.

Following comprehensive tutorials and schematics he found on the Internet, Breitschmitt welded together his own biodiesel production system for well under $4,000. He’s quick to point out that recycled parts have kept the cost down—his system uses an old washing machine motor and several used oil drums.

Following online tutorials, Breitschmitt welded together his own biodiesel production system for well under $4,000

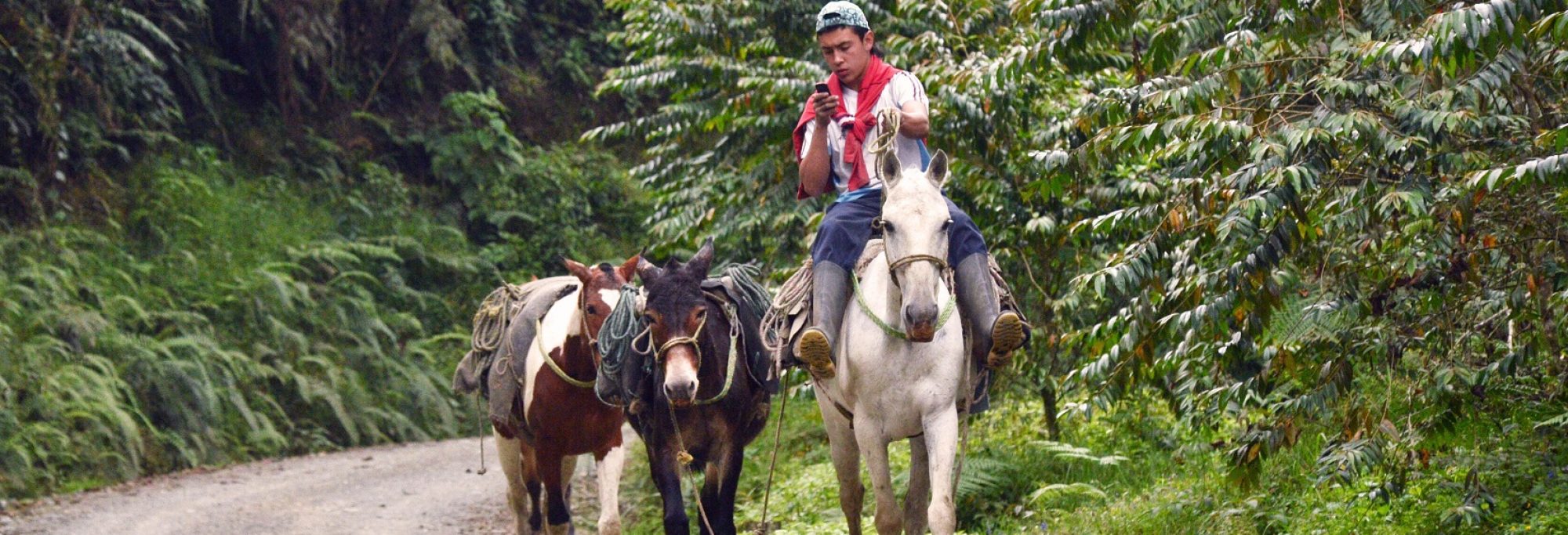

For his cooking oil, Breitschmitt drives over to the nearby city of Pergamino and picks it up for 10 cents a liter from restaurants and school cafeterias. Sometimes he gets his oil from the Monsanto seed factory outside Pergamino. Monsanto’s cafeteria feeds 1,000 employees, Breitschmitt says, most of them migrant workers from Argentina’s northern provinces.

By mixing the used cooking oil with methanol and sodium hydroxide, he makes one 200-liter batch of biodiesel per week, sometimes two, depending on the season. This is enough to run his farm’s two tractors and two pickup trucks.

Breitschmitt says the initial investment was well worth it. Each batch costs him $75, a fraction of the $250 he would be spending at the gas station. And besides the government-imposed monthly quota of 5 kilograms of sodium hydroxide each person can buy, there is no limit to the amount of biofuel one can produce. But like most biodiesel producers, he’s wary of using 100% homemade biofuel. The cost is higher because he mixes in gas station diesel to make a B60 blend (meaning 60% biodiesel) for his tractors and B40-50 for his Chevy pickup trucks.

Breitschmitt is excited about his project, which he’s named Recup-Oil, and he’s eager to spread the word. Recup-Oil has a hotline people can call to have their used cooking oil picked up. Earlier this year, Breitschmitt went around to several classrooms to talk about recycling cooking oil as a way of reducing dependency on fossil fuels. “The schools are really receptive to these ideas,” says Breitschmitt, “which is great because it’s the children that are going to push this forward.”